| Date | Customer Name | Employer | Project Name | Project Location | Climate Conditions | Device | Item/Qty |

| Jan/23 | Shandong Hualu-Hengsheng Chemical Co., Ltd. | Shandong Hualu-Hengsheng Chemical Co., Ltd. | 300,000 t/y diacid electrical tracing system of Shandong Hualu Hengsheng Chemical Co., Ltd. | Dezhou,Shandong | -27℃~+40℃ | diacid | Self-regulating heating cable/21300m |

Shandong Hualu Hengsheng Chemical Co., Ltd. is one of the top ten leading enterprises in Shandong Province and the main company in the coal-based fine chemical industry chain. It has been designated by the State-owned Assets Supervision and Administration Commission of the State Council as a benchmark for the management of key state-owned enterprises. It has been recognized as the energy efficiency leader in the coal-based synthetic ammonia, methanol, acetic acid, and other industries for eight consecutive years. The company’s operational efficiency, labor productivity, and other financial indicators have consistently ranked among the top in similar enterprises. It has been listed multiple times in the “Top 500 Chinese Listed Companies” and “Top 100 Listed Companies in Terms of Value.” The company has taken the lead in drafting or revising national standards and industry standards for several products, including trimethylamine and DMF. It has also led the drafting of the safety specifications for chemical plant start-up in Shandong Province, and DMF has been selected as a national single-champion product in the manufacturing industry.

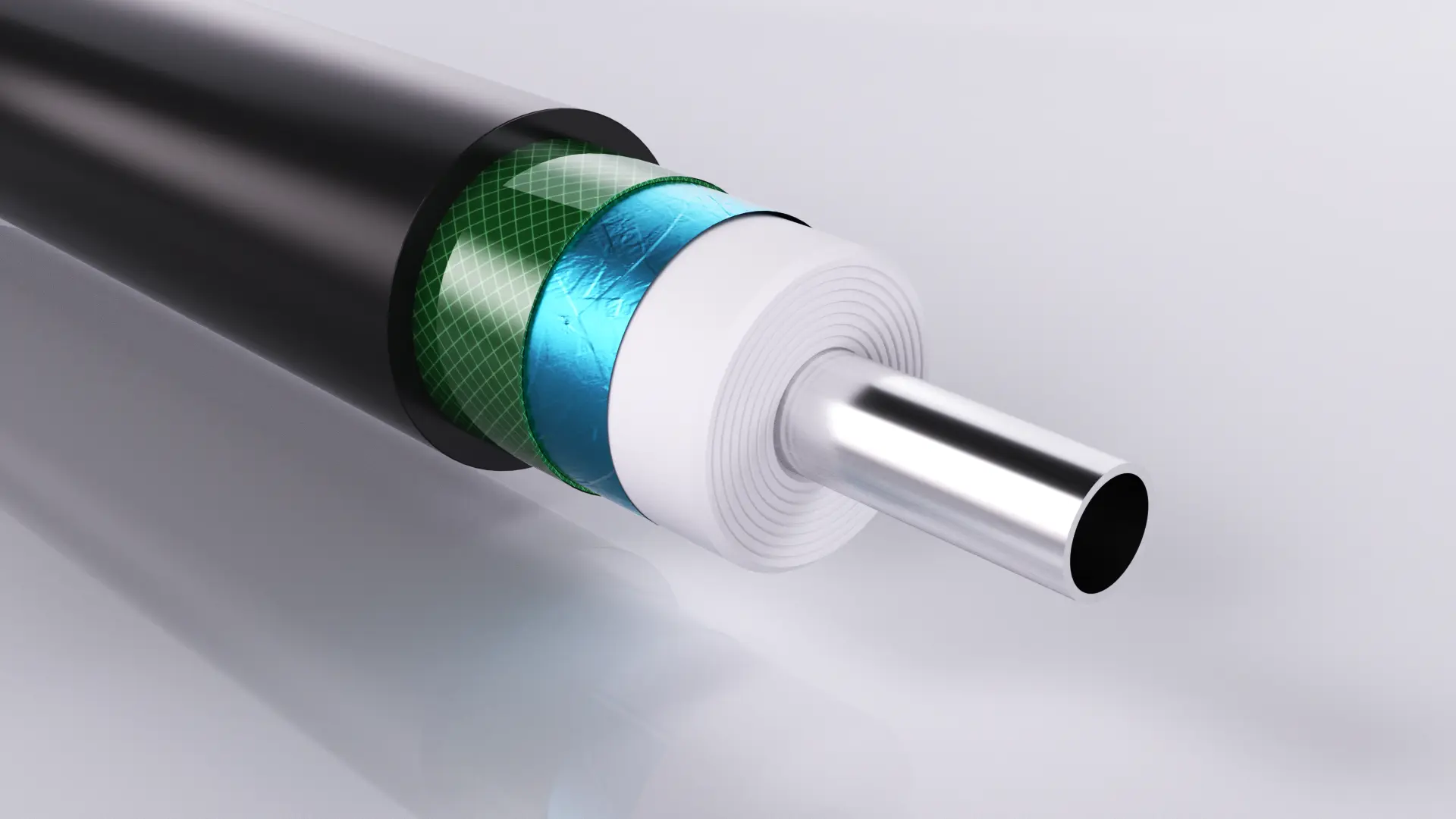

Project Introduction: This project is a benchmark in the domestic high-end chemical industry. One of the substances involved, dimethyl oxalate, needs to be maintained at a temperature of 130°C. It has the characteristics of high freezing point, easy crystallization, and requirements for more valves and flanges. The heating for the pipes in the plant area is provided by high-temperature self-regulating heating cables. Our company has designed the HTS high-temperature cable, which can withstand temperatures up to 205°C and maintain a maximum temperature of 150°C. It has stable performance. The first phase of the dimethyl oxalate project has been successfully operated for four years and has been unanimously recognized by the engineering department and workshop of the company.