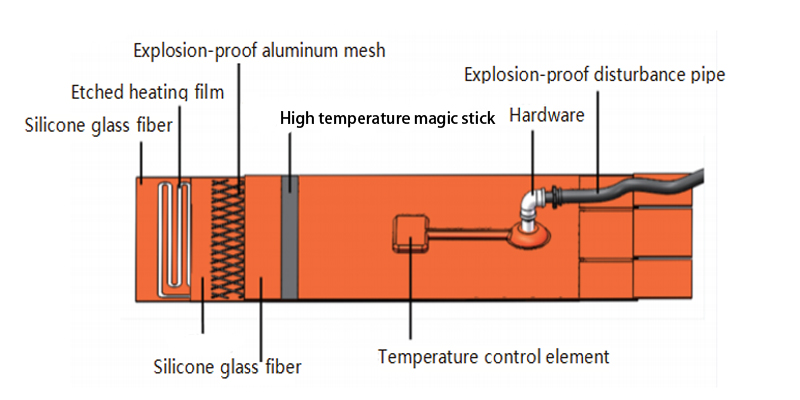

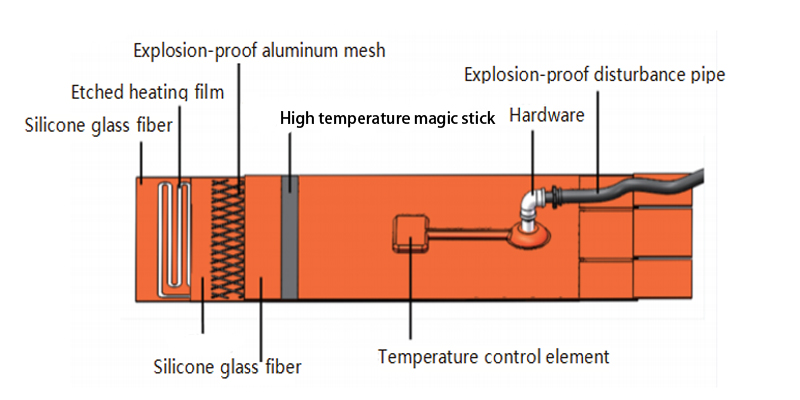

Product Structure

Product Superiority

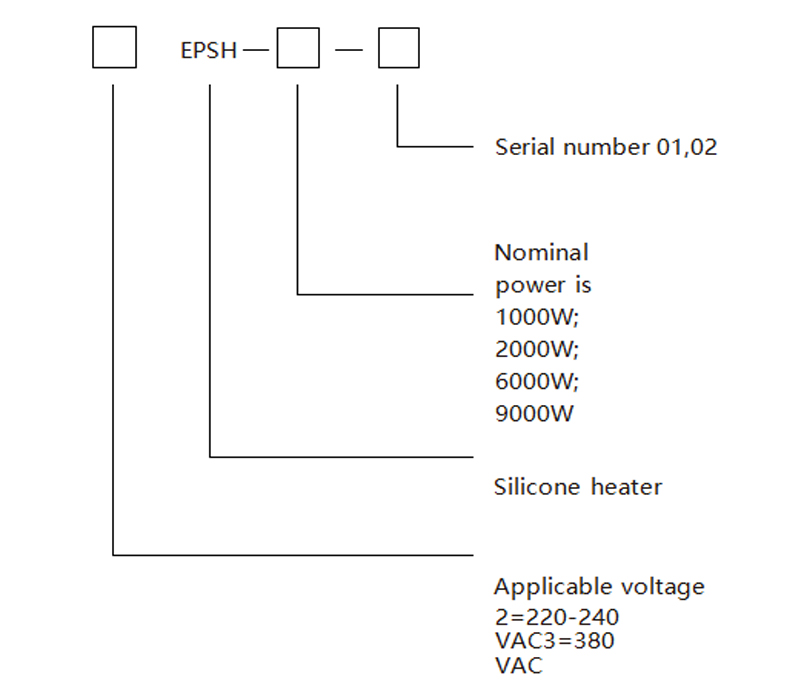

The main heating element inside the EPSH silicone heater is the etched series heating film, which can provide uniform surface dimension temperature with large heating area and uniform distribution. The insulation material is silicone rubber glass fiber cloth, which has high temperature resistance conditions and waterproof effect, and has an enhanced glass fiber woven cloth inside, to meet the needs of temperature resistance, but also specific and very good tensile strength. In order to enhance the safety and reliability of the product, the built-in grounding explosion-proof network can effectively provide the circuit grounding protection. Using integrated structure design and overall sulfurization forming process, built-in overtemperature protection element and PT 100 temperature measuring element, to realize temperature monitoring and control. It can be used in the explosion-proof areas and safe areas.Has a matching aviation power connector, with the temperature controller for use.