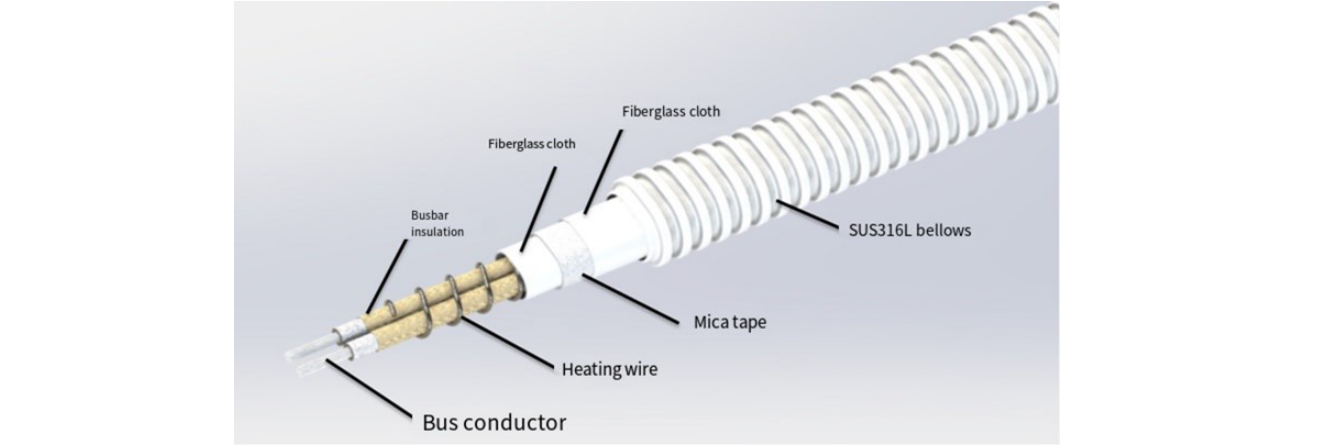

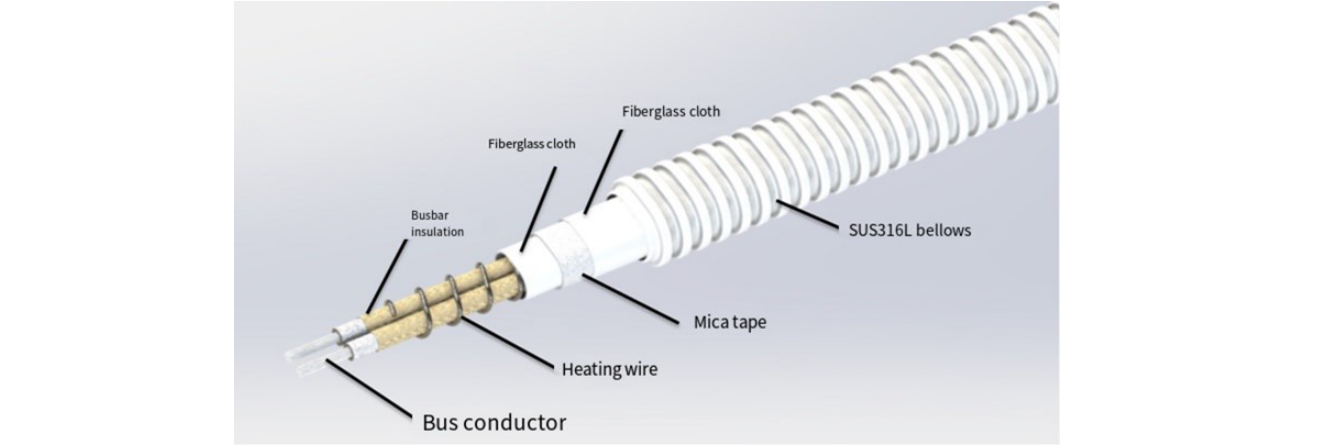

The main heating element inside the parallel constant power electric tracing belt of BWG is actually the heat

ing conductor wound on two parallel bus bars. The heating conductor is wound on two parallel bus bars

respectively with a fixed length of heating section to form a connection point, ensuring the same heating

power of each heating section and forming a heating effect of constant power. The parallel bus itself, between

the parallel bus and the outside of the heating conductor has inorganic insulation layer or combination layer

for insulation treatment, and then the external armored bellows outer sheath as protection, forming a com

plete product structure.

It can be used in explosion-proof areas and safe areas as specified in the certification.

With a full set of matching accessories, you can ensure a longer service life of the product through a standardized power connection and tail packaging.