Characteristics of SCW Constant Wattage Heat Tracing Cable

Temperature stability: Constant output power to meet the requirements of stable power output within a wide temperature range. It is easy to monitor and control, ensuring precise temperature maintenance.

Easy to bend: It can be easily installed in a winding manner on pipelines and equipment with smaller diameters, and has lasting reliability. It can achieve folded bending.

Convenient design: Since there is no obvious starting current, additional considerations do not need to be made for electrical design and circuit breakerselection.

Arbitrary trimming: The characteristics of parallel circuits allow on-site trimming and installation within the maximum length range of the circuit.

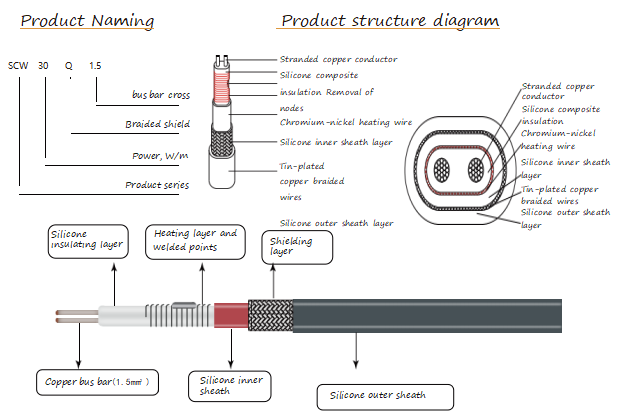

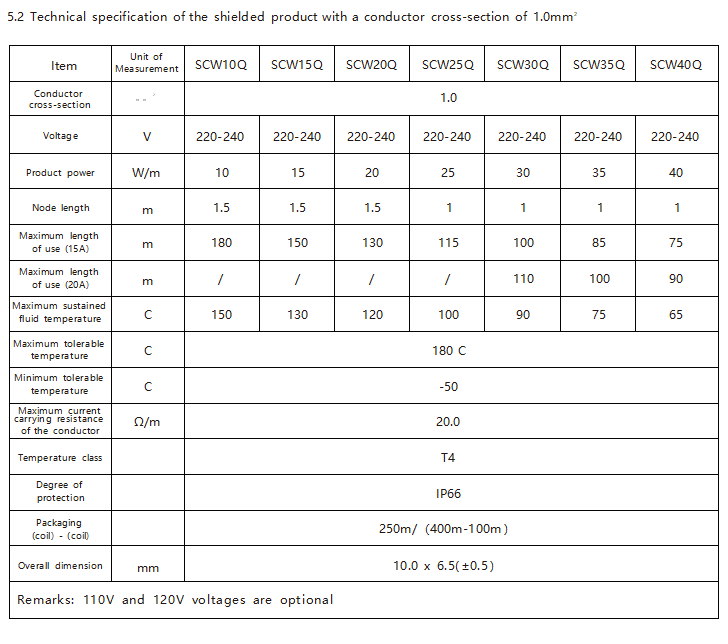

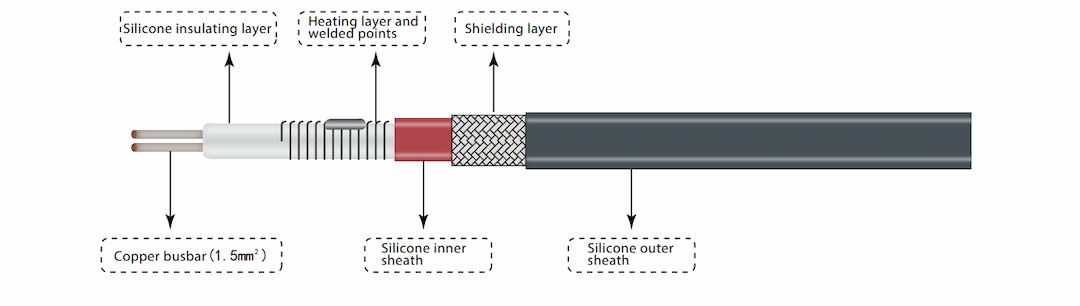

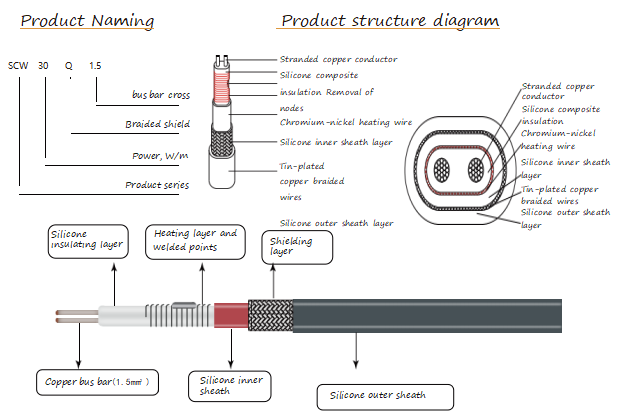

Safe to use: The structure of the tin-plated copper shielding layer has anti-electromagnetic interference and good mechanical characteristics, and it can be used as a grounding wire.

Environmentally friendly and pollution-free: The materials are composed of silicone rubber and metal wires, free from any pollution.

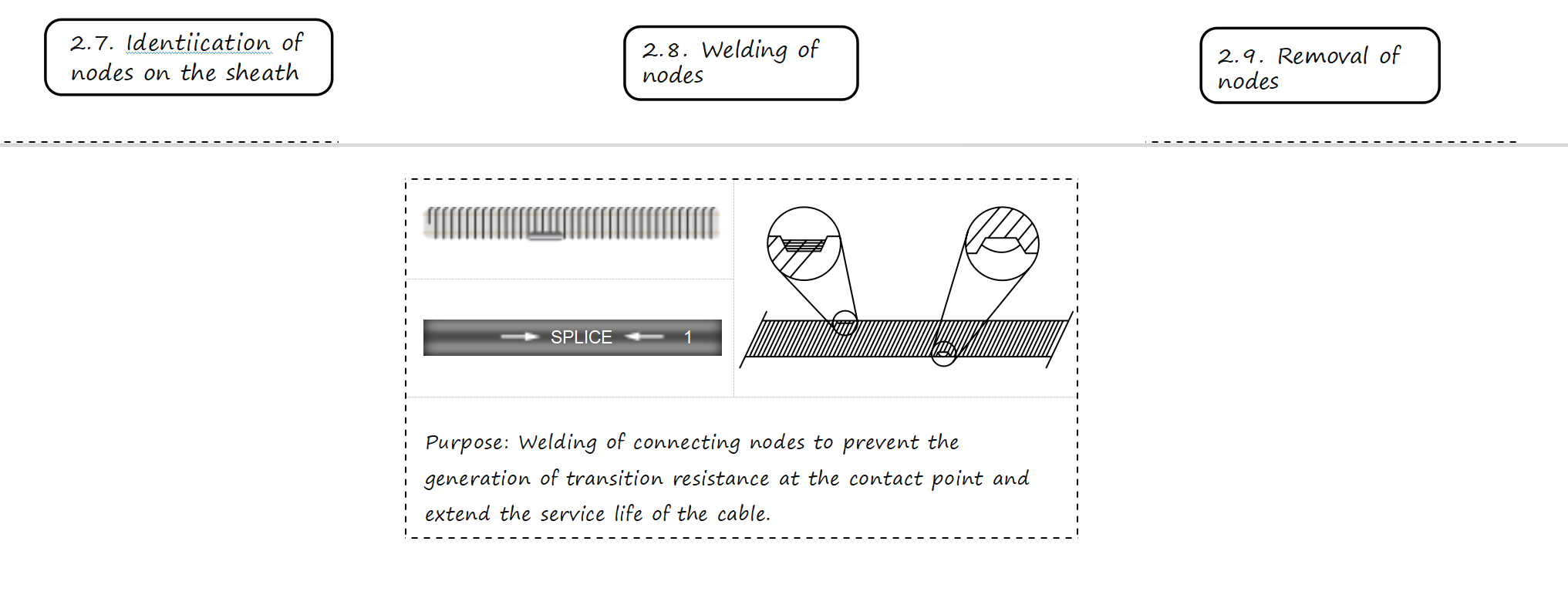

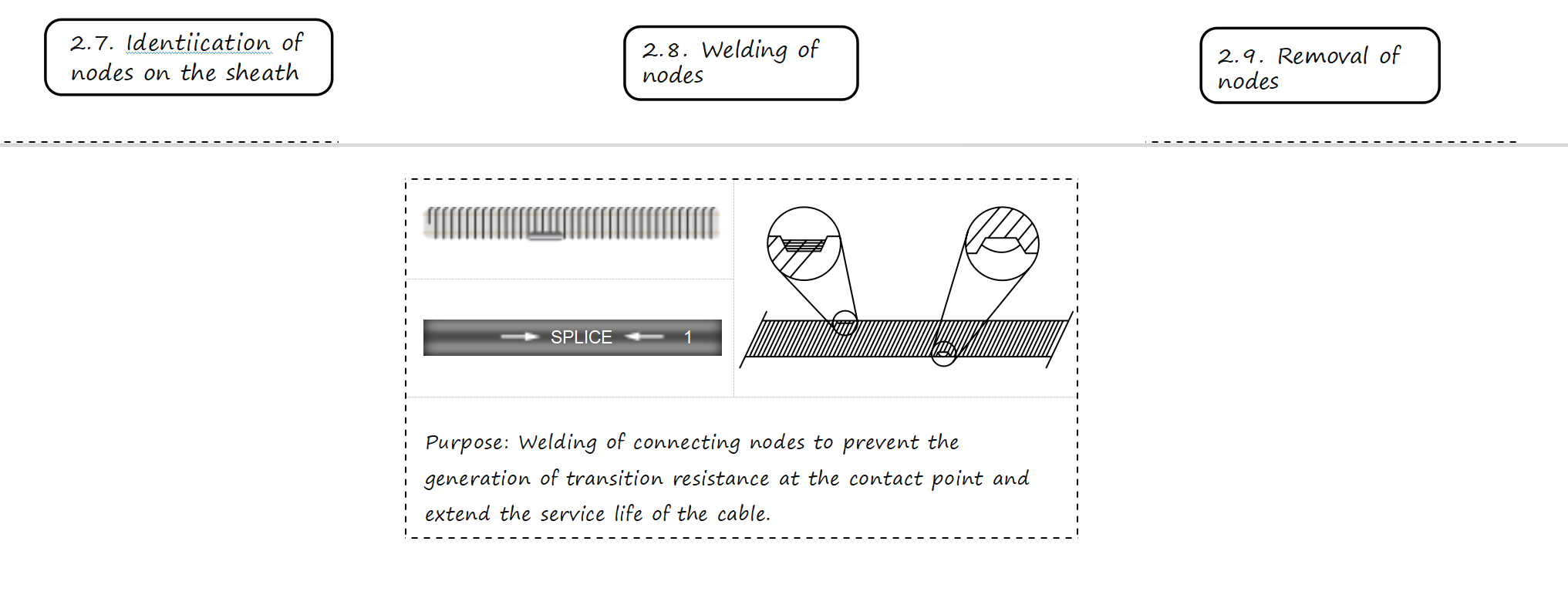

Identification of node sheaths Welding of nodes Removal of nodes

Product introduction

Product applications

SCW parallel constant wattage heating cables are suitable for maintaining liquid low temperature in lower ambient temperatures, applications such as liquid anti-freezing, and temperature maintenance in process systems. For example, they are used in finished oil pipelines, process water systems, dust removal systems, lubricating oil pipelines, condensate return lines, hot water pipelines, para in pipelines, asphalt pipeline storage tanks, etc.

Pipeline freeze protection and temperature

In the processing of liquid medium processing in chemical plant pipelines, heat dissipation occurs, resulting in a decrease in temperature inside the pipelines, which in turn causes the liquid media to condense and block the pipelines when cooled.

SCW is used for antifreeze and temperature maintenance in chemical plant pipelines. When used in conjunction with a temperature controller, it can accurately maintain the temperature of the pipeline or heating medium.d.

Instrument freeze protection

For instrument pipelines, when the measured medium is transmitted to the transducer through the measuring pipeline, freezing, coagulation, and crystallization precipitation often occur due to low environmental temperatures, thus affecting the accuracy of instrument measurement display.

SCW is used for various aspects of work in industrial settings such as power plants, oil, chemical plants, water plants, etc., including instrument antifreeze and wastewater treatment.

Tank heat tracing

Tanks or vessels require moderate freeze protection or even temperature maintenance to prevent changes in viscosity, crystallization of chemicals, etc. of the stored liquid due to temperature changes.

SCW is installed at one-third of the position from the bottom of the tank to facilitate heat conduction and circulation within the tank.

Applications of Products in the Semiconductor Industry

High-Purity Gas and Media Delivery

High-purity gas delivery is one of the critical facilities in the semiconductor industry, including integrated circuits, lat panel displays, light-emitting diodes

(LEDs), photovoltaics, opticalibers, and other semiconductor-related ields.

SCW is used for thermal management of gas circulation pipelines within the equipment, as well as for waste gas treatment and exhaust heat recovery.

High-Purity Chemical Delivery

High-purity chemical delivery mainly involves ultra-high purity chemical supply systems

(equipment) and high-precision chemical blending systems (equipment).

SCW is used to maintain speciic temperatures during chemical delivery processes and for system drainage and exhaust heating.

Semiconductor Material

Quality control is a crucial linkin the production of

semiconductor materials. Monitoring parameters such as temperature, pressure, and composition during the growth process is essential.

SCW is used for temperature control in the preparation and processing of semiconductor materials.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi