Application Of Heat Trace Tubing Bundle In The CEMS

What is the CEMS?

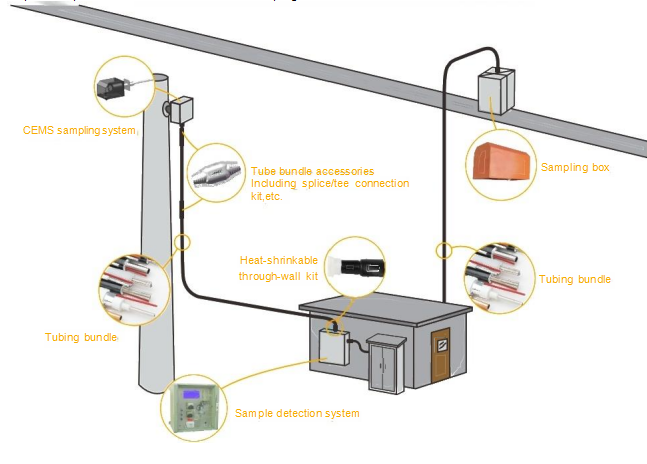

CEMS stands for Continuous Emissions Monitoring System, i.e., an integration system that continuously monitors the concentration and total emissions percentage of gaseous pollutants from air pollution sources, then transmits the detection value to the official department in real-time. According to the classification of sampling technology, CEMS testing can be divided into direct measurement method, dilution method, and extraction method, and the dry measurement method in the extraction method meets the requirements of our environmental protection standards.

Why apply the electrical heat trace tubing bundle?

The CEMS using the dry measurement method needs to transmit the sampling object to the sampling equipment via the sampling pipeline. However, the sampling object includes sulfur dioxide, nitrogen oxide, water steam, etc. The temperature of the transmission pipeline must be maintained at 120℃ to 160℃ level, or even 180℃, so as to prevent the cases that the water steam liquefied, and the sulfur dioxide dissolved in water which turns into sulfuric acid due to the decrease in temperature. Otherwise, the measurement results will be affected. In this way, water in the flue gas can exist in the form of steam. Meanwhile, it can also prevent water condensation. Otherwise, sulfuric acid will be formed with sulfur dioxide. Therefore, the heat trace tubing bundle becomes the optimal solution.

What are the requirements for the electrical heat trace tubing bundle adapted to CEMS?

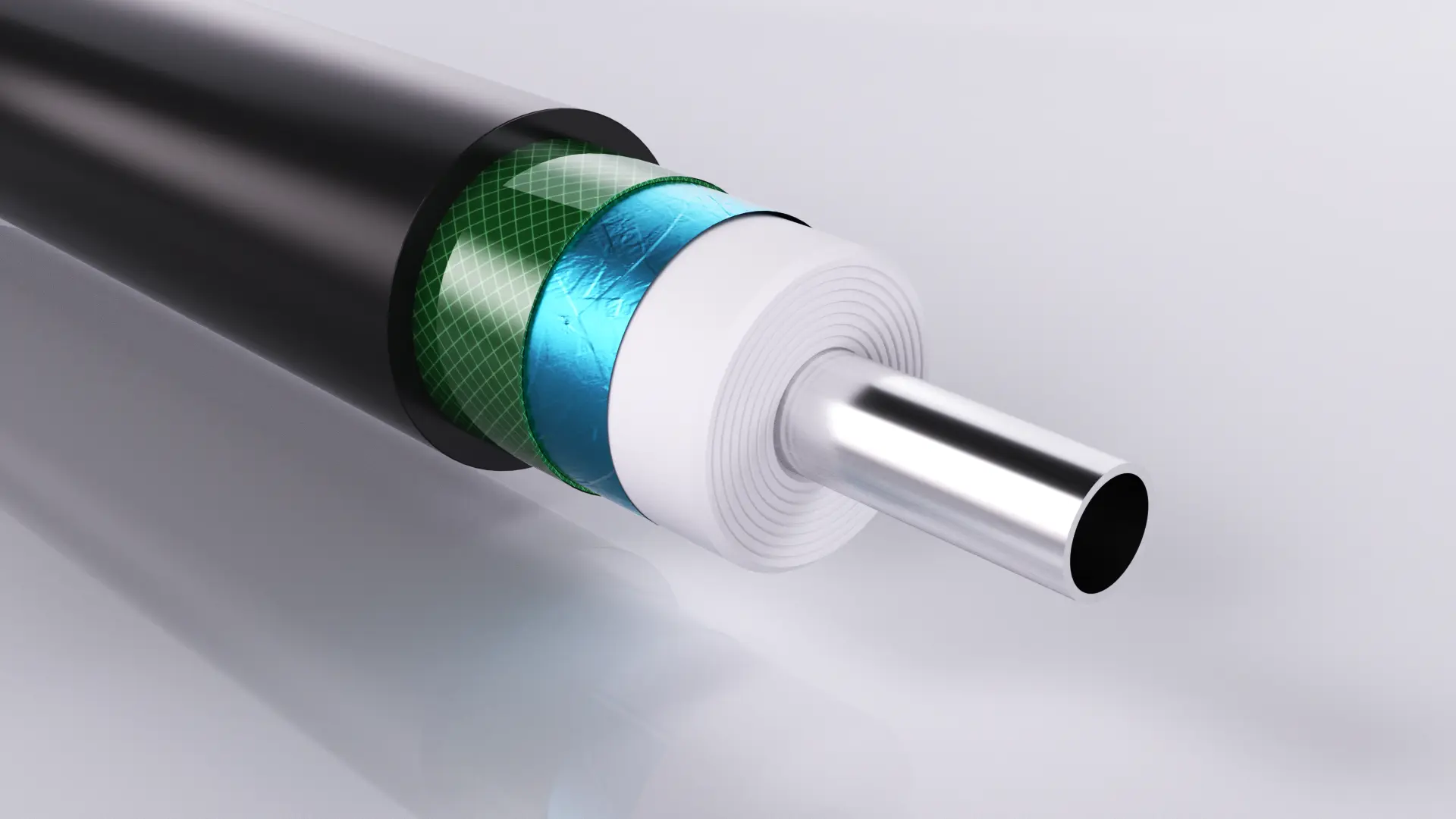

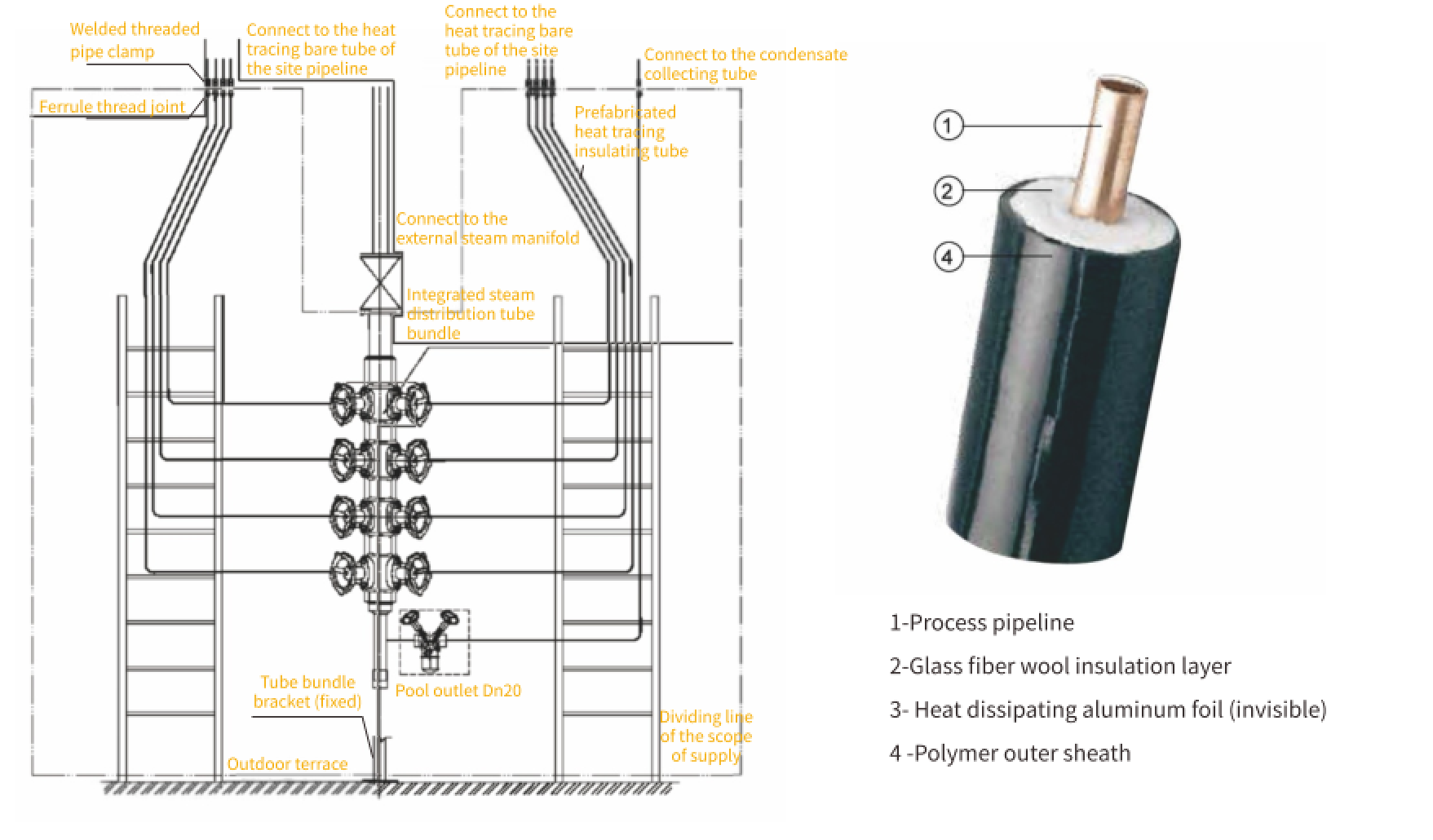

The commonly used intergrated heat tracing bundles adapted to CEMS are usually powered by 220VAC, 50Hz. The maintained temperature ranges from 120℃ to 160℃ depending on the systems with different bands and requirements. Therefore, the adapted integrated heat trace tubing bundles are mainly high-temperature self-regulating tracing cable and power constant tracing cable, with the power output of about 35W/m. The material of the sampling tube used is PTFE with an outer diameter of 6mm.

EN

EN

ja

ja  ko

ko  fr

fr  de

de  es

es  it

it  ru

ru  pt

pt  ar

ar  vi

vi