Heating cables play a vital role in many industrial and commercial applications. They are designed to maintain the temperature of pipes, equipment or other systems to ensure proper operation. Regularly checking the working condition of your heating cables is a critical part of maintaining system efficiency and safety. Here's a detailed inspection guide to make sure your heating cable is working properly.

Preparation before inspection:

Before performing any inspection, be sure to turn off the power and ensure the safety of the workplace. Have the necessary testing tools ready, such as a resistance tester, thermometer, or infrared camera.

Eye exam:

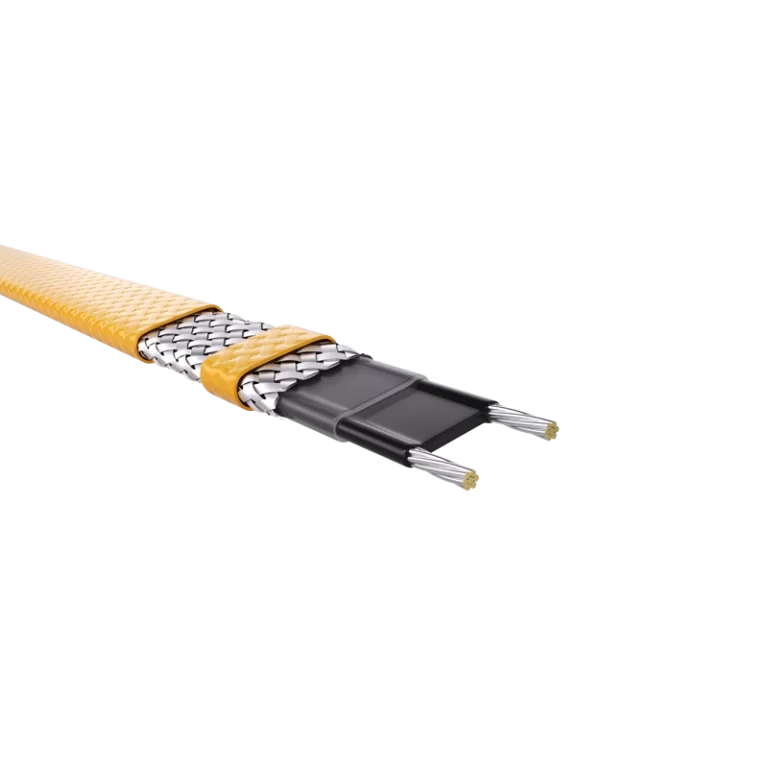

Some cosmetic problems can be quickly discovered through visual inspection. visually inspect for damaged exterior insulation, loose connections, or exposed wires. Any of these problems may affect the proper operation of the cable.

Test resistance:

Use a resistance tester to measure the resistance of a cable to evaluate its connectivity and integrity. Abnormal resistance values may indicate a break or other problem with the cable that requires immediate repair.

Check the power supply:

Ensuring the normal operation of the power supply system is an important part of ensuring the normal operation of the heating cable. Check equipment such as fuses, circuit breakers and mechanical thermostats to make sure they are not faulty or damaged.

Temperature test:

Use a thermometer or thermal imaging camera to test the operating temperature of the self regulating heating cable. Make sure the temperature meets design specifications to verify that the cable is within normal operating range.

Troubleshooting:

List common problems that can cause heating cables to not work properly, such as faulty thermostats, broken cables, etc. Solutions and fix recommendations are provided for each issue so that issues can be fixed promptly.

Best quality heating cable

If you want to get high-quality heating cables but don't know how to choose, try Wuhu Jiahong. As a professional manufacturer of heating cables, Jiahong can provide you with high-quality products and excellent services. Welcome to contact us for detailed ordering information!

The importance of regular inspections:

Stress the importance of regular inspections of heating cables to help detect potential problems early and avoid system failure. It is recommended to develop a regular inspection schedule to ensure the long-term reliability of the system.

By following the above methods and steps, you can ensure the normal operation of the heating tape, thereby ensuring the normal operation of your production and system. Regular inspections not only help improve system performance, but also reduce repair and replacement costs and ensure a safe production environment.