As the demand for effective heat trace solutions continues to grow across various industries, it becomes increasingly important to understand the different types of self-regulating heat trace cables available in the market. With applications ranging from traditional industrial settings to specialized industries and extreme environmental conditions, each type of heat trace cable offers unique features and benefits. In this article, we will explore the characteristics, applications, and considerations associated with traditional, high-temperature, low-temperature, and industry-specific self-regulating heat trace cables.

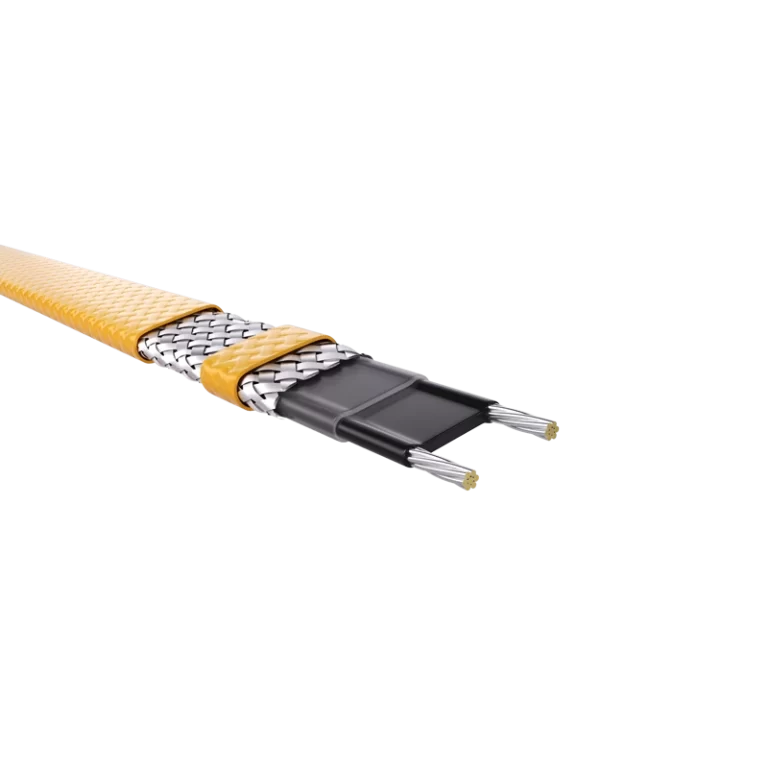

Traditional Self-Regulating Heat Trace Cable

Traditional self-regulating heat trace cable operates on a simple yet effective principle. As the temperature decreases, the electrical resistance of the cable increases, generating more heat to compensate for the loss. This type of cable finds widespread use in various industries such as oil and gas, chemical processing, and commercial buildings for applications including freeze protection, temperature maintenance, and snow melting. While traditional self-regulating heat trace cable offers versatility and reliability, it is important to consider its limitations, such as maximum temperature capabilities and power output constraints.

High-Temperature Self-Regulating Heat Trace Cable

Designed to withstand extreme heat, high-temperature self-regulating heat trace cable is engineered to maintain consistent performance in industrial settings where elevated temperatures are a constant factor. Its unique construction and advanced materials allow it to operate reliably in environments where traditional cables would fail. Specific applications include process temperature maintenance, heat preservation in pipelines, and thermal management in refining and petrochemical facilities. When comparing high-temperature self-regulating heat trace cable with traditional variants, it is essential to consider factors such as temperature range, durability, and overall performance under extreme conditions.

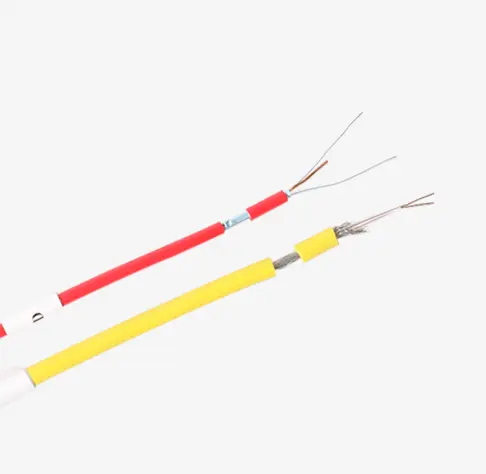

Low-Temperature Self-Regulating Heat Trace Cable

In contrast to high-temperature cables, low-temperature self-regulating heat trace cable is tailored to excel in cold climate environments. Its ability to provide consistent heat output, even in sub-zero conditions, makes it an ideal solution for applications such as winterization of residential and commercial properties, ice and snow melting on roofs and gutters, and freeze protection for water pipes. The unique properties and functionality of low-temperature cables make them indispensable for maintaining safe and operational infrastructure in cold regions. However, careful consideration of ambient temperatures, power requirements, and insulation is crucial when deploying low-temperature self-regulating heat trace cable systems.

Self-Regulating Heat Trace Cable for Specific Industries

Customized self-regulating heat trace cable solutions are developed to meet the unique requirements of specific industries, such as food and beverage, pharmaceuticals, and transportation. These tailored solutions address industry-specific challenges, ensuring compliance with regulations, safety standards, and operational needs. Case studies showcasing successful implementations of industry-specific heat trace cable solutions demonstrate their effectiveness in enhancing productivity, ensuring product integrity, and minimizing downtime.

The best Self-Regulating Heat Trace Cable manufacturer in 2024

If you want to get the best Self-Regulating Heat Trace Cable, you might as well try jiahong. As a professional Heat Trace Cable manufacturer, jiahong can provide you with high-quality products and perfect services. Welcome to contact us for detailed ordering information and services!

In conclusion, understanding the different types of self-regulating heat trace cable is essential for selecting the most suitable solution for specific applications. Whether it's traditional, high-temperature, low-temperature, or industry-specific heat trace cable, each type offers distinct advantages and considerations that must be evaluated based on the unique requirements of the intended application.