Introduction

The debate between heat tape and heat cable often arises in applications like pipe freeze protection, roof de-icing, and industrial process heating. While both solutions aim to prevent freezing or maintain temperature, their design, performance, and suitability vary significantly. This article focuses on constant wattage heat cables—a subset of heat cables—and compares them with conventional heat tapes to help users make informed decisions.

1. Definitions and Key Differences

Heat Tape

Structure: Typically a flat, flexible ribbon-like product, often made of rubber or silicone with embedded heating elements.

Function: Primarily used for residential pipe freeze protection. Some basic models lack advanced temperature control and rely on manual activation.

Lifespan: Generally 3–5 years but may degrade faster if exposed to UV rays or mechanical stress.

Heat Cable

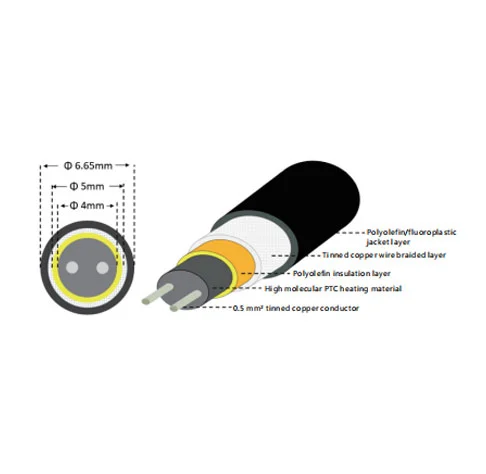

Structure: A robust, insulated cable with conductive cores (e.g., nickel or copper alloys) and protective jacketing. Subtypes include:

Constant Wattage Heat Cable: Delivers fixed heat output per unit length, ideal for uniform heating in predictable environments.

Self-Regulating Heat Cable: Adjusts power output based on ambient temperature.

Applications: Suitable for industrial pipelines, roof de-icing, and large-scale floor heating due to higher durability and precision.

2. Performance Comparison

Heating Efficiency

· Produces a consistent heat output (e.g., 5–20 W/ft) regardless of external conditions. This ensures reliable performance in stable environments like long pipelines or floor heating systems.

· Drawback: Higher energy consumption in warmer conditions since it cannot self-adjust.

· Often lacks precise temperature control. Basic models may overheat or underperform in fluctuating climates.

· Energy efficiency varies; some modern tapes include thermostats but still lag behind self-regulating cables.

Durability and Lifespan

· Designed for industrial use with materials like fluoropolymer insulation, resistant to chemicals and high temperatures. Lifespan ranges from 10–20 years with proper maintenance.

· Prone to wear in harsh environments. Prolonged exposure to moisture or physical stress can cause cracks or electrical failures.

3. Cost Analysis

Initial Investment

Heat Tape: Lower upfront cost (typically 1–1–3 per foot), making it popular for DIY projects.

Constant Wattage Heat Cable: Higher initial price (around 3–3–7 per foot) due to specialized materials and engineering.

Long-Term Costs

Heat Tape: Frequent replacements and higher energy bills (if unregulated) increase total ownership costs.

Constant Wattage Heat Cable: Despite higher initial costs, its longevity and stable performance reduce maintenance expenses. However, energy bills remain fixed, unlike self-regulating alternatives.

4. Installation and Maintenance

Ease of Installation

Heat Tape: Lightweight and flexible, suitable for DIY installation on small pipes or gutters. However, improper overlap can cause hotspots.

Constant Wattage Heat Cable: Requires professional installation due to strict spacing requirements. Overlapping is prohibited to prevent overheating, and thermostats are often needed for temperature control.

Maintenance Needs

Heat Tape: Regular inspections are critical to detect wear or electrical faults.

Constant Wattage Heat Cable: Minimal maintenance due to robust construction, but periodic checks of insulation and connections are recommended.

5. Application-Specific Recommendations

Residential Use (Pipe Freeze Protection)

Heat Tape: Suitable for short, accessible pipes in mild climates.

Constant Wattage Heat Cable: Ideal for long, complex pipe networks requiring uniform heating, especially in regions with consistent cold.

Industrial and Commercial Use

Constant Wattage Heat Cable: Preferred for chemical plants, oil refineries, and large-floor heating due to reliability and high heat output.

Heat Tape: Limited to non-critical, small-scale applications.

Roof and Gutter De-Icing

Self-Regulating Cables: Better for energy efficiency in variable weather.

Constant Wattage Heat Cable: A viable alternative if budget constraints exist, but ensure thermostat integration to avoid overheating.

6. Environmental and Safety Considerations

Heat Tape: Risk of fire if damaged or improperly installed. Limited suitability for hazardous areas.

Constant Wattage Heat Cable: Built with flame-retardant materials and certifications (e.g., UL, ATEX) for safe use in explosive atmospheres.

Conclusion

The choice between heat tape and heat cable hinges on specific needs:

Heat Tape offers affordability and simplicity for small residential tasks.

Constant Wattage Heat Cable excels in demanding industrial applications requiring durability and consistent heating.

For energy-sensitive scenarios, self-regulating cables may outperform both, but constant wattage remains a cost-effective solution for stable environments.

When selecting, prioritize factors like lifespan, energy costs, and environmental conditions. Consulting professionals is advised for complex installations.