Heating cables are essential for the maintenance of a pipe and vessel temperature. As such, before going ahead to purchase any product, there is a need to understand the product and the things you should look out for when buying the product.

Chapter 1. Why Heating Cable is Important?

Chapter 2. Application of Heating Cables

Chapter 3. How to select a reliable Suppler?

Conclusion

Therefore, buying a heating cable is not an exception, and as a result of this, we have put together everything you need to get the best heating cable.

Graphic: Heating Cables

This guide will teach you how to choose heating cable and how to find a reliable supplier in China.

Chapter 1: Why Heating Cable is Important

Heating cables are essential for the maintenance of a pipe and vessel temperature, and they are essential because of the following reasons below:

They help to create a slow melt, which can eventually lead to the elimination of the hazards related to long-term and consistent ice buildup.

It can also help to reduce and eliminate ice damming.

A heating cable is also an excellent option for house owners who have poorly shielded homes. However, it is good to note that a heat cable won’t fix the problem, but a heating cable decreases some of the energy lost from the attic.

It is excellent for harsh environment weather conditions because it has excellent resistance to flame.

It is also essential because it provides excellent resistance to the chemical.

Some heating cables are essential because they do not need an additional management facility or costs after the first installation.

It is needed because it reduces the load on the building, and this is a result of the thin thickness.

The heating cable is vital in reducing the number of circuits, and it is available for voltages of up to 400 Vac.

They help to prevent damage and wastage for industries that are into production.

Conclusively, they make life easier for everyone.

Chapter 2: Application of Heating Cables

The application can be in two forms which are: residential & commercial or industrial. We explain these two different applications below.

3.1 Residential & Commercial Application:

3.1.1 Electric Floor Heating

Have you noticed that during the cold season, the floor can be freezing, and walking around bare feet is the last thing you’d want to do, right?

Now, with the help of an electric floor heating, you have less thing to worry about during the cold season.

This is because you can walk around to experience the comforting warmth of heated tiles on your bare feet.

Graphic: Floor Heating ( ← Click to get a complete solution)

3.1.2 Freeze Protection

Freeze protection is another way of applying heating cable. Under the Freeze Protection, we have

Graphic: Pipe Freeze Protection

– Pipe freeze protection

They are essential because, in cold climates, water or chemical pipework often needs to be heat traced to prevent freezing.

It ensures that the pipe is clear or free of ice to enable it to perform its function appropriately.

Pipe freeze protection is in two ways,

– Drain Pipe Heating (PVC Pipes)

– Water Pipe Heating (Metal Pipes/in pipe heating cable/ pipe heat trace)

Water Pipe Heat Cable can help protect your cold-water and hot-water pipes from freezing during frigid temperatures or weather.

It helps to prevent water damage and bursting of pipes in sub-freezing temperatures.

Graphic: water pipe freeze protection

Also, it is safe to use, and it conserves energy. It keeps water flowing down to -40 degrees Fahrenheit. Furthermore, one of the many benefits of this water pipe heating is that it is quite easy to use.

– Freezer Door Deicing

Freezer doors get exposed to several temperatures. These freezer doors experience temperature differences from inside and outside of the freezer.

When these doors are opened and closed often, condensation can build up on the sliding channel and freeze.

Therefore, there is a need to prevent this from occurring by getting a freezer door de-icing. You should place it on the door frame behind the door track.

The freezer door de-icing works by spontaneously adjusting its heat output based upon ambient conditions, and it prevents exceeding a specific rated temperature, most commonly 149°F (65°C).

– Agriculture through heating

The heating cable is also for agricultural purposes.

The heating cable helps with frost-free watering places. A frost-free watering-place is an investment because it promotes the health of your animals.

It also prevents damage to your water pipes and buildings.

It is available in different lengths and sizes, depending on the type you want.

3.1.3 Snow Melting

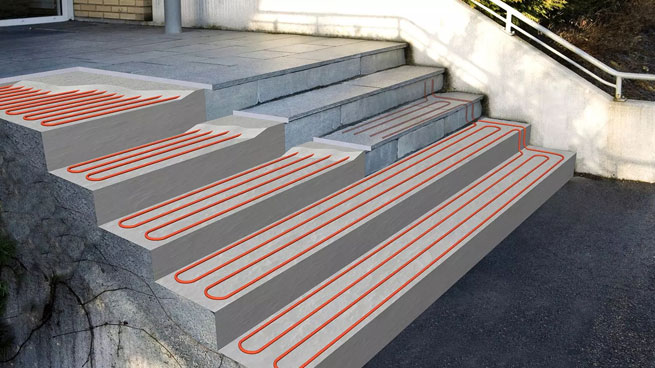

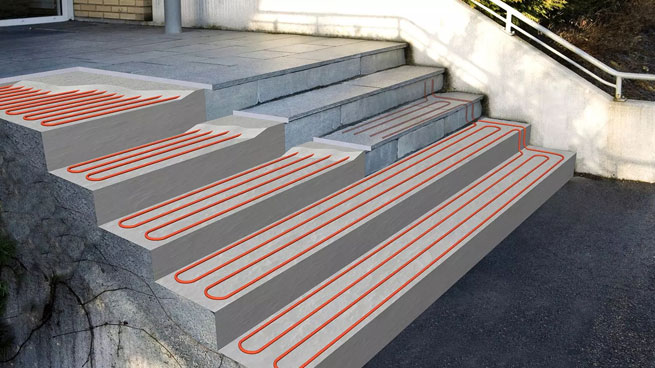

Heating cables can also be used to ensure that the driveways, stairs and entrance areas to homes and other places are snow and frost-free throughout the winter season.

What people hardly know is that snow melting systems consumes far less energy and are cheaper to use and maintain than most realize.

– Driveway Snow Melting

Driveway, courtyard, and other outdoor areas can be quite challenging to drive through or walk through during the winter season, but you can solve this with a heating cable.

Graphic: Driveway Snow Melting

The heating cable can help to keep the driveway free from snow and ice.

The installation of the heating cables can happen over larger areas; one can install it in the wheel tracks, in a staircase, or walkways.

Graphic: Courtyard Snow Melting

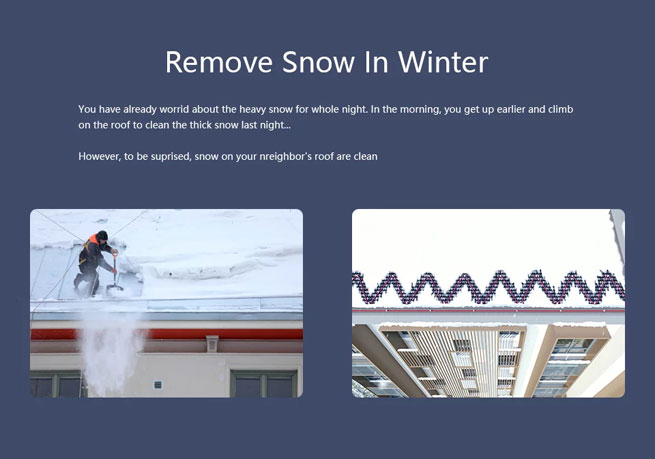

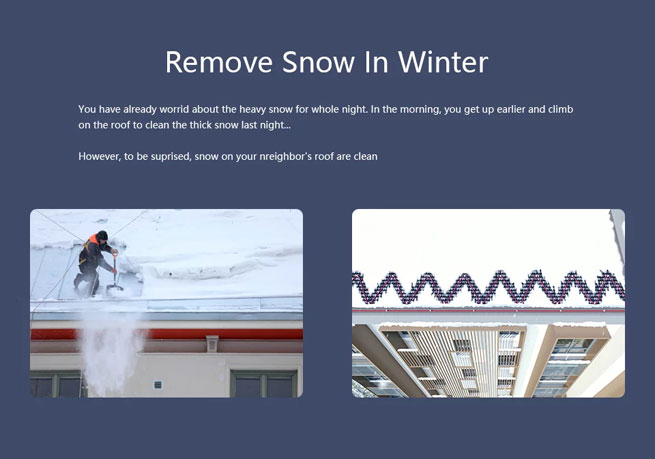

– ROOF & GUTTER DE-ICING

Accumulation of ice and snow on the top of your roof and inside your gutter can lead to costly water damage in your home or office.

Graphic: Remove Snow By heating cable or By yourself

Hence, installing roof and gutter de-icing can help to prevent trapped water in the roof or gutter, which may lead to leakages, decay, or even roof breakdown if too much accumulates on it.

It is also quite affordable to purchase and requires less maintenance. Plus, it is safe to use.

This is to prevent any elements from bad weather, such as snow and ice, from building up, and eventually, it helps the football club from postponing any match.

3.2 Industrial Application:

These industrial applications of heating cables are used for high output requirements, where the operating temperatures are very high.

They are best for heating of vessels, containers, valves and many other applications listed below:

The oil and gas production,

Storage facilities

Petrochemical plants

Refineries

Pharmaceutical production

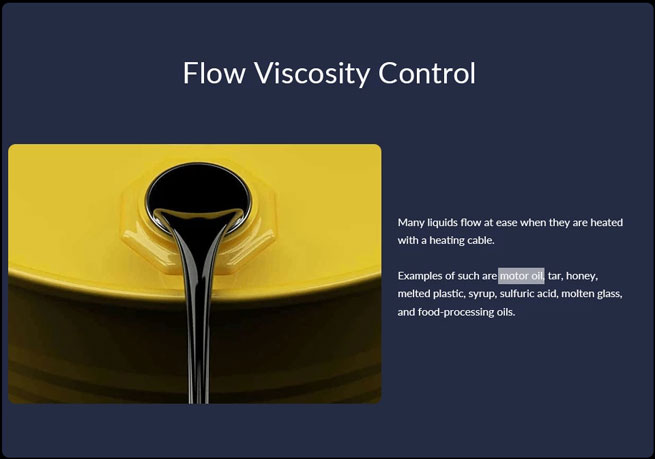

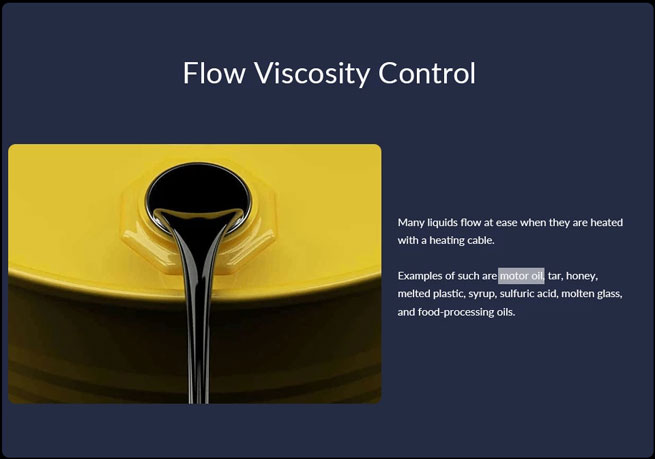

3.2.1 Flow Viscosity Control

For industrial applications, keeping your liquid flowing at a peak level is very important, and the use of a heating cable can help you achieve this goal.

Many liquids flow at ease when they are heated with a heating cable. Examples of such are motor oil, tar, honey, melted plastic, syrup, sulfuric acid, molten glass, and food-processing oils.

As a result, the right heating cable can help with the flow viscosity control and maintain these lines at the right temperature to secure that it can move through a pipe.

3.2.2 Biodiesel Drum Heating

Biodiesel refers to vegetable oil or an animal fat-based diesel fuel, which comprise of a long-chain alkyl.

Biodiesel is also known as a renewable fuel for use in diesel vehicles, generators, and homes. It can also be used as heating oil, and it provides a safe and efficient heating source.

Using biodiesel drum heaters can help to provide a practical and efficient means for viscosity control.

When purchasing a biodiesel drum heating, you should look out for the following features below:

Ensure it has moisture, chemical, oil, and radiation-resistant.

3.2.3 Petrochemical viscosity control

Petroleum-based chemicals often thicken, and as such, they do not flow well at lower heat temperatures.

Inability to resolve it can lead to it getting thick, and this can lead to clogging, which can reduce work productivity the petrochemical industry.

As a result, the heating cable is installed along the pipe that keeps the petrochemical flowing to maintain the elevated temperatures necessary for petrochemical production.

3.2.4 Process Temperature Maintenance

There are times whereby you may have a procedure that needs an increased temperature for the work to be carried out.

The procedure means that you need to maintain a temperature for the work to be carried out successfully.

– Cosmetics heating

Cosmetic creams and lotions manufacturing company’s needs to make use of the process temperature maintenance.

They need this because their product makes use of a mixture process in which oil, wax, and fat component are mixed with a water element and an emulsifying agent.

This is important because the uniform dissemination and precise control of temperature are vital to this application to avoid the hardening or burning.

This is essential for the formula to be constant from one product to the next one.

– Gas handling

When gas gets expelled from the gas cylinder, the pressure drops inside the cylinder.

The pressure drops, leading to the temperature inside the cylinder to reduce, which makes it very difficult for the gas to vaporize and be ejected.

As a result of the inability of the gas cylinder to eject the content inside, it leads to gas wastage, an extension of production time, and increased production costs.

In most cases, the gas cannot be rapidly expelled as a result of the cold weather, which leads to freezing.

As a result, the cylinder must be warmed before work is carried out.

– Liquid Caustic soda temperature maintenance

Liquid caustic soda, which is known as sodium hydroxide, is a highly acidic material.

In many industries, it is used as a cleaner, e.g., petroleum refining, chemical processing company, textile companies, pulp and paper, and chemical processing.

As a result, the temperature must be maintained at a specific temperature, which is usually above 70°F (21°C) to prevent freezing.

Lack of proper maintenance of the temperature leads to reduced efficiency, blockage, and reduced work productivity.