Series constant power and parallel constant power are two important configurations in electric heat tracing systems. They have significant differences in structure, working principles, performance characteristics, and application scenarios.

Structural Differences

Series Constant Power Electric Heat Tracing Tape

The structural characteristic is that the resistance wire is connected in series with the electric heat tracing tape.

The structure of series constant power electric heat tracing tape can be divided into single-core, two-core, and three-core types. Generally, single-core series electric heat tracing is used in combination with three tapes of the same length rather than individually.

Parallel Constant Power Electric Heat Tracing Tape

The structural characteristic is that the resistance wire is connected in parallel with the electric heat tracing tape.

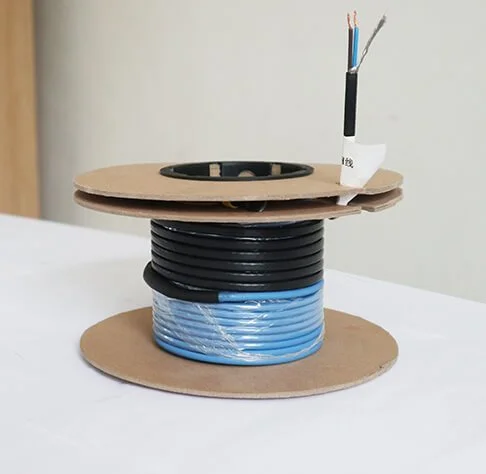

The structure of parallel constant power electric heat tracing tape is relatively complex, including two (or three) parallel insulated copper wires as the power bus, with conductive wires wound on the insulation layer and connected to the power bus at certain intervals to form a continuous parallel resistance.

Working Principle

Series Constant Power Electric Heat Tracing Tape

The current starts from the power source, passes through each series-connected electric heat tracing tape in sequence, and finally returns to the power source.

Since all electric heat tracing tapes are connected in series in the same circuit, their working voltage is the same, but the current may vary due to different resistances.

The series constant power electric heat tracing tape heats through the core wire, and its output power is not affected by ambient temperature and medium temperature.

Parallel Constant Power Electric Heat Tracing Tape

Multiple electric heat tracing tapes are connected in parallel in the circuit, and each electric heat tracing tape has an independent power access point.

In this configuration, the working voltage and current of each electric heat tracing tape are equal.

Each electric heat tracing tape works independently, allowing for more flexible power output and temperature control.

Performance Characteristics

Series Constant Power Electric Heat Tracing Tape

Advantages: The structure is relatively simple, easy to install, and low cost; it can easily achieve overall control, such as temperature monitoring and regulation; ensures that each electric heat tracing tape receives enough electrical power, thereby ensuring its normal operation.

Disadvantages: If one electric heat tracing tape fails, the entire system may be affected; with all electric heat tracing tapes connected in series in the same circuit, the same working voltage may lead to over or underpowered output in some tapes, affecting their lifespan and safety.

Parallel Constant Power Electric Heat Tracing Tape

Advantages: Each electric heat tracing tape operates independently, so if one fails, others can still work normally; it can easily achieve individual control, such as temperature monitoring and regulation; the power output and temperature range of each tape can be adjusted according to actual needs, enhancing system flexibility and reliability.

Disadvantages: The structure is relatively complex, with higher installation and maintenance costs; requires more power access points and control equipment, possibly increasing system complexity and failure rates; stricter monitoring and management are needed to ensure system safety and stability.

Application Scenarios

Series Constant Power Electric Heat Tracing Tape

Suitable for situations where temperature control requirements are not particularly strict, such as general pipeline insulation and storage tank insulation.

Especially suitable for the petrochemical industry, long-distance pipelines, large tanks, and other power industry occasions requiring long-distance heat tracing.

Parallel Constant Power Electric Heat Tracing Tape

Suitable for large tanks and pipelines in high-temperature demand and explosion-proof areas.

Due to its flexibility and reliability, it is also suitable for occasions requiring precise control of temperature and power output.

In summary, series constant power and parallel constant power each have their advantages and disadvantages in electric heat tracing systems. The choice of configuration should be determined based on specific application scenarios and requirements.