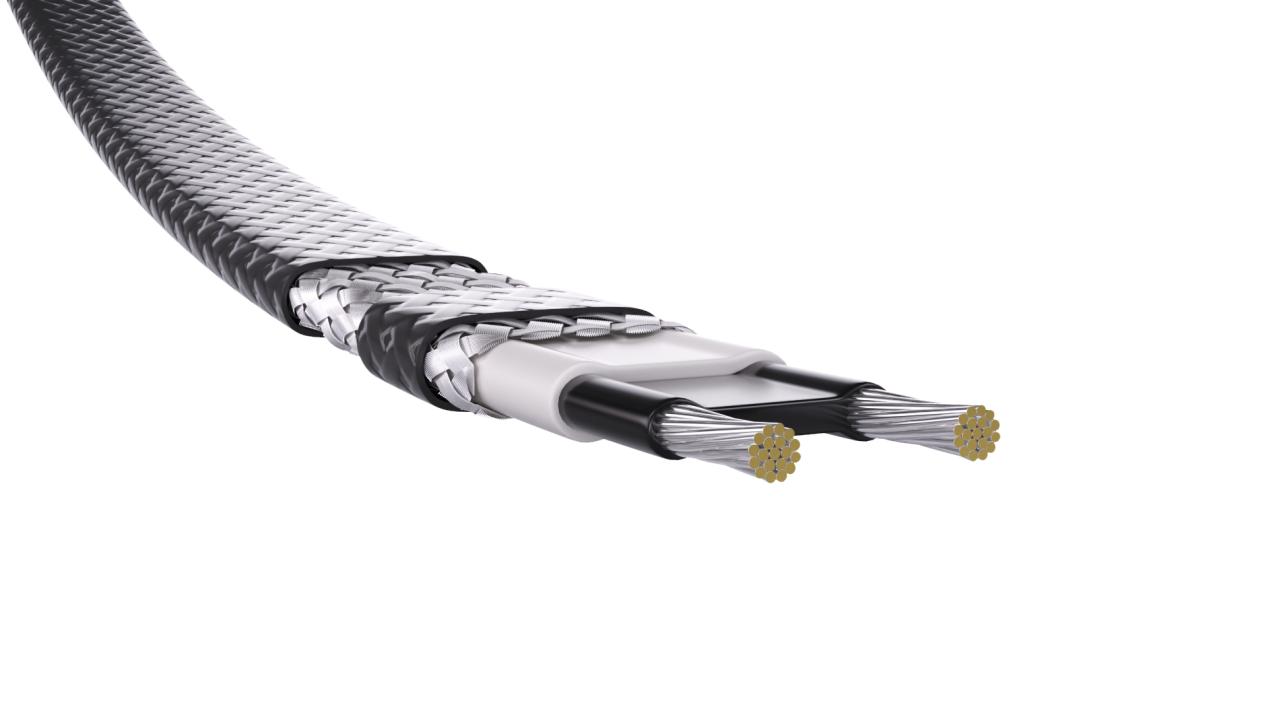

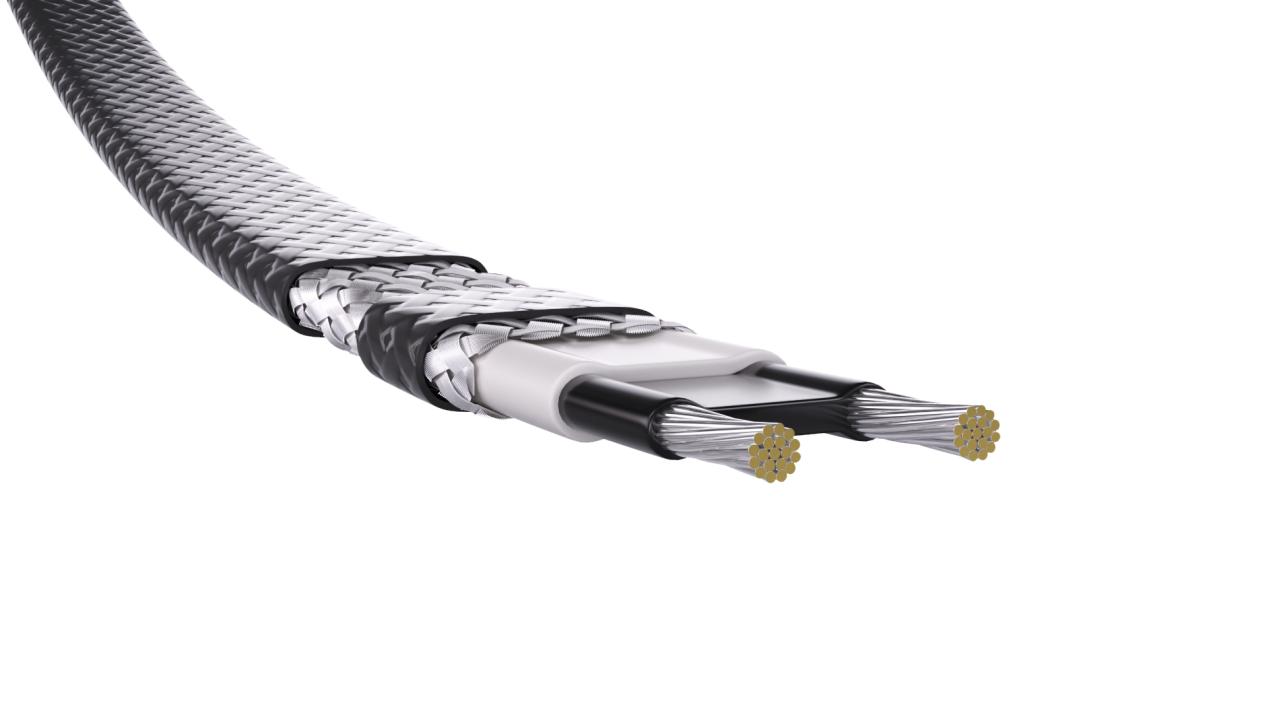

Heating cable insulation consists of an inner and outer jacket, providing double-layer protection. The inner jacket is extruded around the core wire to provide insulation and protection. The outer jacket is then extruded over the inner layer, increasing the mechanical strength during the stretching process of the heating cable. The main function of the outer jacket is to protect the core insulation from mechanical damage caused by external forces, as well as to prevent the infiltration of moisture and the leakage of impregnating agents. Heating cables are primarily classified into self-regulating and constant power heating cables. This includes low, medium, and high-temperature self-regulating heating cables, parallel and series constant power heating cables, MI (mineral-insulated) cables, underfloor heating cables, silicone rubber heating cables, and more.

The materials used for the heating cable insulation vary, which also determines the suitable application areas for these heating cables. For example, self-regulating heating cables often have a jacket made of materials such as polyolefin or PVC (polyvinyl chloride), with fluoropolymer materials (180°C) or perfluorinated materials (205°C) for high-temperature applications. PVC jackets offer corrosion resistance, mold resistance, and are suitable for pipelines exposed to corrosive media, long-term underground burial, outdoor snow-melting or ice-thawing applications, boilers, and steam pipelines. However, PVC jackets tend to be rigid, making installation more difficult and increasing costs. Therefore, for general explosion-proof or damp areas, self-regulating heating cables with polyolefin jackets are recommended. Users can determine whether the purchased heating cable is suitable for the installation environment based on the material properties of the heating cable.

Here are the common materials used for heating cable jackets available in the market:

Polyolefin

Abbreviated as PO, polyolefin in electric heating tape jackets is a thermoplastic resin made from the polymerization of olefins. As a polymer material with a relatively less dense molecular structure, it has good high and low-temperature resistance, excellent chemical stability, and is suitable for most environments requiring acid and alkali resistance. It is insoluble in general chemical solvents at room temperature, has low water absorption, and excellent electrical insulation properties. However, polyolefin is very sensitive to environmental stress (chemical and mechanical actions) and has poor heat aging resistance. It is often used for the outer jacket insulation of electric heating tapes. To enhance the material's temperature resistance, irradiation crosslinking modification is usually employed, which can significantly increase the operating temperature of polyolefin. This specially processed polyolefin insulation layer can better exhibit its moisture-proof and antifungal properties, with its chemical properties becoming more stable.

Polyvinyl Chloride

Abbreviated as PVC, it is a polymer of vinyl chloride. It has good chemical stability and resists corrosion from acids, bases, and some chemicals. It is moisture-resistant, aging-resistant, and flame-retardant. However, its usage temperature should not exceed 60℃ and it becomes hard at low temperatures. The insulating layer of the PTC core belt in self-limiting heating tapes is mostly composed of polyvinyl chloride.

Cross-linked Polyethylene

Abbreviated as XLPE, it is a technology that enhances PE's performance. Cross-linking modification greatly improves PE's mechanical properties, environmental stress cracking resistance, chemical corrosion resistance, creep resistance, and electrical properties, and significantly raises its temperature resistance from 70℃ to over 90℃. Therefore, it broadens PE's application range significantly. Currently, cross-linked polyethylene is often used for the inner insulation layer of heating cables.

Magnesium Oxide

High purity, high temperature, electrically fused crystalline magnesium oxide is the best thermal insulator due to its ability to withstand temperatures up to 2000℃. The insulation layer of MI heating cables is composed of mineral magnesium oxide powder.