Overloading heating cables is a common problem that can lead to serious consequences such as equipment failure, safety hazards, and even fires. Therefore, it is crucial to take precautions to prevent overloading your heating cables.

Overloading the heating cable can cause the following problems:

Equipment failure: Overloading can cause the temperature of cables and related equipment to rise beyond their designed working range, thereby damaging the cable insulation and wires, and even causing equipment to burn out.

Safety hazards: Overloaded cables may cause safety accidents such as circuit short circuits and fires, posing serious threats to people and property.

Energy waste: Overloading will lead to increased energy loss in the cable system, resulting in energy waste.

The main causes of overloading heating cables include:

Poor design: Poor design of a cable system may result in the cable being unable to withstand the required load.

Improper Cable Sizing: Selecting an inappropriate cable size may result in the cable being unable to meet the required load requirements.

Overload: Use that exceeds the cable's rated load may cause the cable to be overloaded.

To prevent overloading of heating cables, the following measures can be taken:

Reasonable design of cable systems: When designing cable systems, cable types and specifications should be reasonably selected based on actual load requirements, and ensure that the capacity of the cable system is sufficient to meet the load requirements.

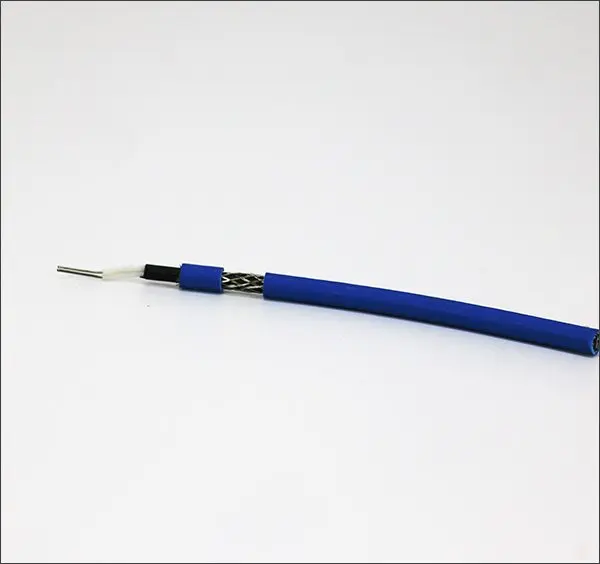

Buy high-quality heating cables: There are various types of heating cables on the market now. Choosing high-quality heating cables is a task that cannot be underestimated. If you don’t know how to choose, you might as well try Jiahong, as a professional heating cable manufacturer , jiahong can provide you with high-quality products and services. Welcome to contact us for detailed ordering information!

Determine Proper Cable Sizing: Based on the load requirements and cable length, select the appropriate cable size to ensure that the cable can handle the required load without overloading.

Install protection devices: Install overload protection devices, such as fuses or overload protection switches, in the cable system to cut off the power supply in time when the cable is overloaded and protect the cables and equipment.

Avoid using multiple cables in parallel: When designing a cable system, avoid using multiple cables in parallel to avoid unbalanced loads and cable overloading.

Regular inspection and maintenance: Regularly check the operating status of the cable system, including cable connections, insulation status, etc., to discover and solve potential problems in a timely manner to prevent overloading.

Establish a reasonable operation management system: Establish and implement an operation management system for the cable system, including load management, equipment maintenance, etc., to ensure the safe operation of the cable system.