The mineral insulated heat tracing system is an efficient, safe, and reliable heating solution, widely used in various situations requiring insulation or heating.

System Composition

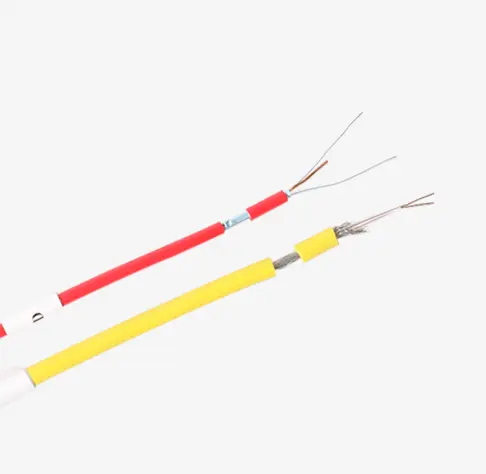

The mineral insulated heat tracing system primarily consists of a metal sheath, mineral insulation material, and a heating wire. The metal sheath serves to protect and support, while also aiding in heat dissipation; the mineral insulation material, with its high insulation and high-temperature resistance performance, effectively isolates the heating wire from the external environment, ensuring the safe operation of the system; the heating wire is the core component of the system, which generates heat when electrified, transferring the heat to the heated object through the mineral insulation material.

Working Principle

The working principle of the mineral insulated heat tracing system is based on the thermal effect of electric current. When current passes through the heating wire, heat is generated due to the resistance of the heating wire. This heat is transferred to the heated object through the mineral insulation material, thereby raising its temperature to achieve insulation or heating.

Features and Advantages

High-temperature resistance: The mineral insulation material has high-temperature resistance, allowing the system to operate stably in high-temperature environments.

Corrosion resistance: The mineral insulation material also has good corrosion resistance, capable of resisting the erosion of various corrosive media, thus extending the system's service life.

High mechanical strength: The combination of the metal sheath and mineral insulation material provides the system with high mechanical strength, capable of withstanding certain external forces and pressures.

Safe and reliable: Due to its good insulation performance and high-temperature resistance, the mineral insulated heat tracing system is highly safe during use. Additionally, its self-limiting temperature characteristics can prevent safety hazards such as fires caused by excessive temperatures.

Energy-saving and environmentally friendly: The system can accurately control heating power, avoiding unnecessary energy waste, meeting modern industrial requirements for energy-saving and environmental protection.

Application Fields

The mineral insulated heat tracing system is widely used in various situations that require insulation or heating, especially in some special industrial environments such as high temperatures, high pressure, and strong corrosive environments. For example, in the fields of petrochemicals, power, and civil use, the mineral insulated heat tracing system is used for the insulation and heating of pipelines, storage tanks, reactors, and other equipment. Additionally, in the semiconductor industry, the mineral insulated heat tracing system plays a significant role in ensuring temperature stability and product quality of various process equipment.

Installation and Maintenance

Installation

The installation of the mineral insulated heat tracing system is relatively simple. It only needs to be wrapped around the pipeline or equipment that requires heating and connected properly to the power supply. During installation, care should be taken to maintain the system's flatness and tightness to ensure efficient heat transfer.

Maintenance

System maintenance is relatively straightforward, requiring periodic checks of the system's operational status and connections to ensure there are no loose or damaged parts. Additionally, the system should be kept clean and dry to avoid moisture or contamination.