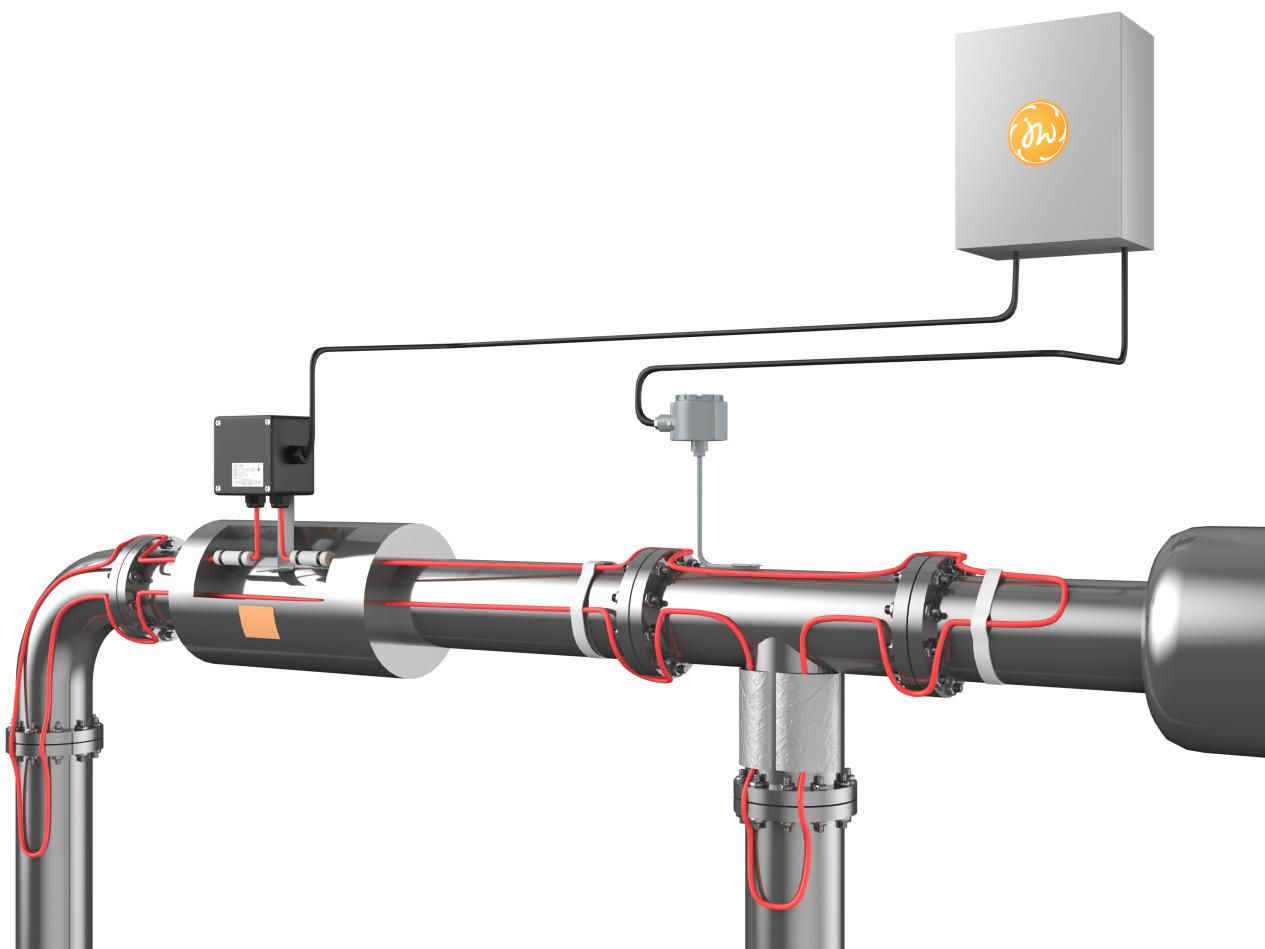

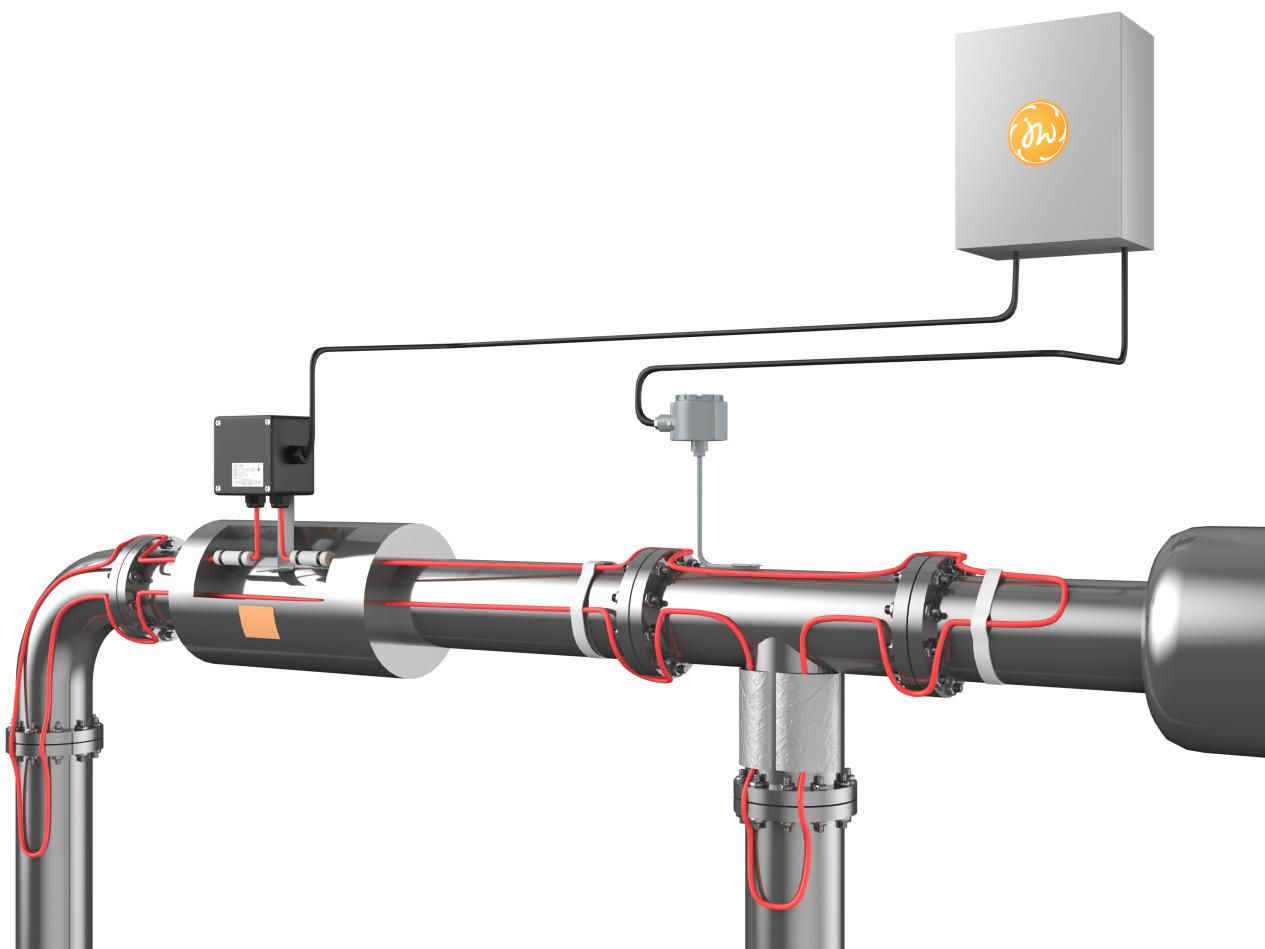

The constant power electric heat tracing system is an efficient and stable heating solution widely used in the industrial field. The system mainly consists of the following key parts:

Electric Heat Tracing Cable

The electric heat tracing cable is the main part of the constant power electric heat tracing system, usually composed of conductive polymers (such as PTC materials) and metal wire cores. These materials can generate heat when powered, thereby heating pipes or other objects. Depending on the connection method, electric heat tracing cables can be divided into parallel and series types.

Power Supply

The power supply provides the necessary electrical energy for the electric heat tracing cable, usually a transformer or power adapter. It converts alternating current into the voltage and current required by the electric heat tracing cable, ensuring the normal operation of the system.

Temperature Controller

The temperature controller is used to monitor and adjust the temperature of the heat tracing system, ensuring the temperature is maintained within a set range. This function is crucial for preventing overheating and maintaining the stability of the heating effect.

Junction Box

The junction box is used to connect the electric heat tracing cable and the power supply, while also providing electrical protection and an interface for maintenance. It ensures the electrical safety and reliability of the system.

Insulation Materials

Insulation materials are used to protect the electric heat tracing cable, preventing electrical short circuits and physical damage. These materials usually have good insulation properties and high-temperature resistance, ensuring the long-term stable operation of the system.

Fixing Devices

Fixing devices such as tapes, clamps, or brackets are used to secure the electric heat tracing cable onto pipes or other heated objects. These devices ensure a close fit between the electric heat tracing cable and the heated object, improving heating efficiency.

End Seal

The end seal is used for the end of the electric heat tracing cable to prevent moisture and contaminants from entering while ensuring electrical safety. This step is important for preventing system failure and extending the service life.

Thermal Sensitive Elements and Safety Devices

Some systems may include thermal sensitive elements, such as thermocouples or temperature sensors, to monitor and feedback temperature information. Additionally, safety devices such as overheating protection, short circuit protection, and leakage protection ensure the safe operation of the system.

In summary, the constant power electric heat tracing system is composed of multiple key parts, each playing an indispensable role. These components work together to ensure the system's efficient, stable, and safe operation. In practical applications, appropriate configurations of the constant power electric heat tracing system should be selected according to specific needs and scenarios to achieve the best heating effect.