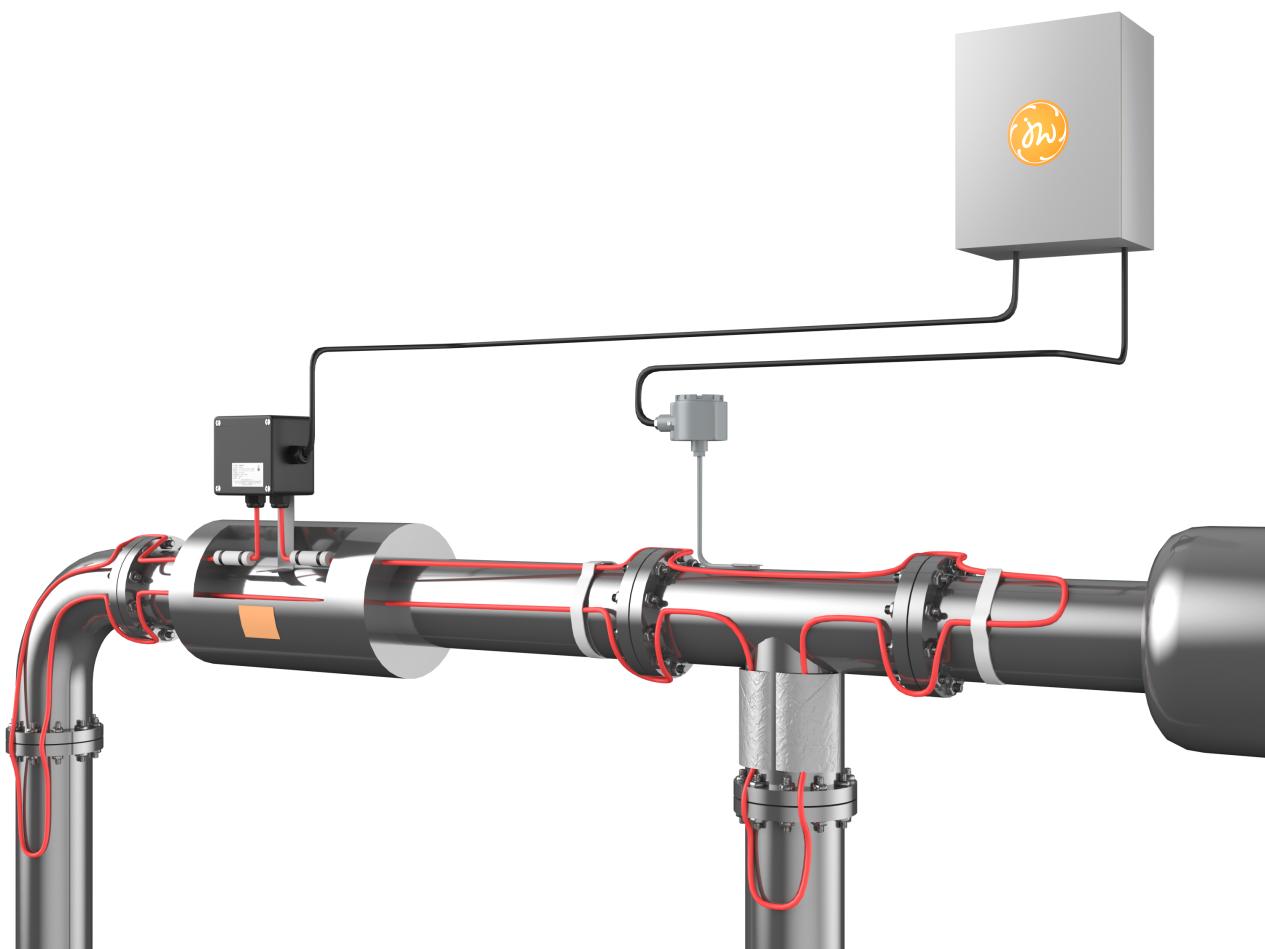

For engineers and facility managers working with industrial heat tracing systems, junction boxes are critical components that ensure safe power distribution and thermal regulation. However, improper installation or grounding can lead to system failures, safety hazards, and costly downtime. This article combines practical installation guidelines with real-world insights from experienced engineers, focusing on optimizing heat tracing junction boxes for reliability and compliance.

1. Why Installation and Grounding Matter: Avoiding Common Pitfalls

Key Risks of Neglect

Electrical hazards: Faulty grounding increases risks of short circuits and electrocution, especially in wet environments like chemical plants or offshore platforms.

System inefficiency: Poorly sealed junction boxes allow moisture ingress, degrading insulation resistance and reducing heat cable performance.

Regulatory non-compliance: Violations of NEC (North America) or IEC (Europe) standards may result in fines or project delays.

Case Study: A Costly Oversight in Alaska

In 2023, a pipeline operator in Prudhoe Bay faced a 72-hour production halt after ice accumulation damaged an ungrounded junction box. Post-failure analysis revealed that salt corrosion had compromised the box’s internal connections—a preventable issue with proper sealing and grounding.

2. Step-by-Step Installation Guidelines

Pre-Installation Preparation

Material Selection:

Use NEMA 4X-rated enclosures for corrosive or outdoor environments (e.g., coastal areas).

Ensure compatibility between box materials (e.g., stainless steel or polycarbonate) and ambient temperatures.

Layout Planning:

Position boxes above flood levels and away from mechanical stress points (e.g., vibrating equipment).

Maintain a minimum 12-inch clearance for maintenance access.

Installation Best Practices

| Step | Action | Engineer Tip |

| 1 | Mounting | “Always use vibration-resistant brackets in high-traffic zones.” – John T., Petrochemical Engineer |

| 2 | Cable Entry | Seal conduit entries with UV-resistant epoxy to prevent moisture ingress. |

| 3 | Wiring | Label all terminals and use torque screwdrivers to avoid over-tightening. |

| 4 | Heat Shrink Tubing | Apply dual-wall tubing at splice points for added insulation. |

3. Grounding Techniques for Maximum Safety

Essential Grounding Components

Common Grounding Mistakes to Avoid

Using undersized conductors: A #12 AWG wire is insufficient for systems exceeding 20A.

Ignoring equipotential bonding: Connect all metallic parts (e.g., conduits, boxes) to eliminate voltage differentials.

Field Example: Refinery Grounding Upgrade

A Texas refinery reduced electrical faults by 40% after retrofitting junction boxes with zinc-coated grounding bars and implementing quarterly resistance tests.

4. FAQs from Engineering Teams

Q: Can I reuse old junction boxes for new heat tracing systems?

A: Only if they pass dielectric testing (min. 2,500V AC for 1 minute) and have intact NEMA/IP ratings.

Q: How often should grounding integrity be checked?

A: Annually for general plants; every 3 months in high-corrosion zones like wastewater facilities.

5. CTA: Optimize Your System Today

Wuhu Jiahong New Material Co., Ltd. offers free PDF installation guides and NEC/IEC-compliant heat tracing kits with pre-assembled junction boxes. Contact us for a customized quote or on-site technical consultation.

By prioritizing robust installation and grounding practices, you can extend the lifespan of heat tracing systems while ensuring worker safety and regulatory compliance. Leverage these insights to turn junction boxes from vulnerability points into reliability assets.

EN

EN