The skin-effect electric heat tracing system is a pipeline heating technology based on the principles of the skin effect, annular effect, and proximity effect of AC current.

Working Principle of Skin-Effect Electric Heat Tracing System

The skin effect refers to the phenomenon where AC current, when passing through a carbon steel conductor, tends to concentrate on the conductor's surface. In a skin-effect electric heat tracing system, this principle is used to generate Joule heat on the pipeline surface, achieving the heating and insulation of the liquid inside the pipeline.

Specifically, the system directs an electric current between the cable in the heating pipe and the outer pipe, utilizing the skin effect to focus the current on the inner wall of the heating pipe, producing Joule heat to meet heating needs. Simultaneously, the annular effect and proximity effect also play significant roles in the system, collectively achieving efficient heating.

System Components of Skin-Effect Electric Heat Tracing System

A skin-effect electric heat tracing system typically consists of the following components:

Power Control Cabinet: Responsible for providing and controlling the AC power supply to ensure the stable operation of the system.

Skin Transformer: Used to convert the power supply voltage to the voltage suitable for the skin-effect electric heat tracing system.

Liquid Transport Pipe: The pipeline through which the liquid is transported; it is the main body of the heating system.

Heating Pipe: Welded onto the liquid transport pipe, containing skin effect cables inside, used to generate Joule heat.

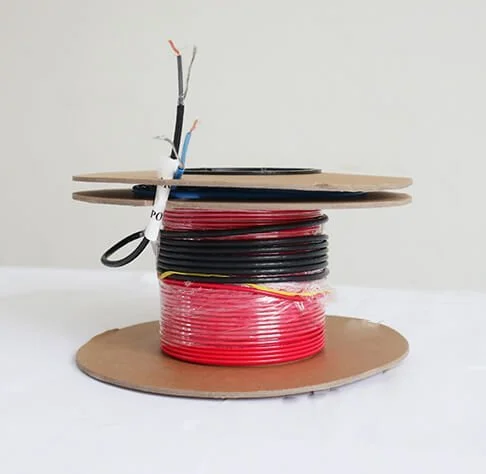

Skin Effect Heating Cable: Core component that generates heat through the current, essential for heating.

Insulation Layer: Used to maintain the temperature inside the pipeline, reduce heat loss, and improve heating efficiency.

Protective Shell: Protects internal components from the external environment, ensuring the safe operation of the system.

Features and Advantages of Skin-Effect Electric Heat Tracing System

High Efficiency and Energy Saving

The skin-effect electric heat tracing system uses isothermal heating methods, achieving high heating efficiency and effectively saving energy. Additionally, the system has self-limiting temperature characteristics, which can automatically adjust the heating power based on actual needs, preventing overheating and further improving energy utilization efficiency.

Safe and Reliable

Since the heating pipe itself forms an insulation structure, it ensures that the liquid transport pipe is always at zero potential, guaranteeing system safety. Moreover, the system has a simple structure, is relatively easy to install and maintain, and requires almost no maintenance during normal operation, reducing safety risks.

Strong Adaptability

The skin-effect electric heat tracing system is suitable for pipeline heating of various liquid substances, whether for long, medium, or short-distance pipelines. Furthermore, the system can be customized based on actual needs to meet different heating requirements in various scenarios.

Intelligent Control

With the development of IoT technology, the skin-effect electric heat tracing system has achieved remote monitoring and intelligent control. Using temperature sensors and other smart devices, the system can monitor pipeline temperature in real-time and automatically adjust heating power, ensuring the safe operation of pipelines and equipment.

Application Areas of Skin-Effect Electric Heat Tracing System

The skin-effect electric heat tracing system is widely used for pipeline heating, insulation, and antifreeze in industries such as petroleum, chemical, and natural gas. Especially in cold regions or winter seasons, this system can effectively prevent pipelines from freezing due to low temperatures, ensuring normal medium transport. Additionally, the skin-effect electric heat tracing system can be applied in nuclear power plants, oil trading transfer stations, and other areas, providing safer and more efficient pipeline heating solutions for industrial production and residential life.